Reflection on developing a digital manufacturing toolkit for children

post by Natalie Leesakul (2018 cohort)

What is the first thought that comes to your mind when you think of manufacturing? Assembly lines? Boring and repetitive tasks? Loud noises?

Over the years, the manufacturing sector has evolved and moved more towards the age of digitalization. However, as the sector entered the era of Industry 4.0, skilled-labour shortages started to become a problem. The sector is experiencing the phenomenon where current employees are retiring while failing to attract new skilled employees. The manufacturing sector was not on my radar until I started my PhD at Horizon CDT (Grant No. EP/L015463/1) working in partnership with DigiTOP (Grant No. EP/R032718/1), and that has completely changed my perspective. This sector is filled with innovation. It is about forward thinking. At the core, there is a major element of maximizing productivity and efficiency by utilizing advanced technologies but also a shift towards ensuring seamless human-machine collaboration and contributions to sustainability and the Net Zero movement. After getting more involved in this sector in the past three years, the question that always comes up is how do we make manufacturing sexy? How do we inspire future generations to be interested in manufacturing?

As part of DigiTOP’s work, we are developing a toolkit to help organizations implement and integrate digital technologies. We provide research on the role of human factors and the impact of technology on the workforce along with use cases and recommendations on the technology adoption and design. One of the on-going toolkit developments is an educational set of resources focusing on the introduction to digital manufacturing aimed at a younger audience (primary and secondary children). I had an opportunity to be a part of the team in charge of developing the content from the start of the video production to running our very first workshop with students in collaboration with Speakers for Schools.

At the start, the first question to answer was how to transform a complex topic into something that is easy to comprehend by the children. We see digital manufacturing as “the use of smart, digital, autonomous and intelligent technologies within the manufacturing sector. These technologies include robotics, virtual and augmented reality, sensors and distributed data networks.” Certainly, there was quite a bit to unpack from this definition. Putting ourselves in the shoes of a 7-year-old, a short animated film was chosen as a communicational medium. Acknowledging that there was not any other existing child-focussed videos on manufacturing at the time, we decided to go forward with the plan and the video was produced in collaboration with Cloudifacturing and Digitbrain projects. The video production kicked off with choosing the right supplier. We searched for a video producer who really understood the brief and the video style of our preference and that required reading through multiple proposals as well as extensive discussion on animation style, colour schemes, voiceover artists, etc. Once we decided on the proposal, we provided the producers with an initial script that covered the objectives and key messages of the video including:

-

-

-

- Introduction to general changes in industry 4.0/digital manufacturing

- Cloud-based technologies and human factors considerations

- Digital twin

- Human physiological sensing

- Human robot collaboration

- Virtual reality in manufacturing and design

- Responsible technology development and adoption

-

-

The challenge we had was explaining all of the above topics in a 3-4 minute video. We consulted with experts in child education to translate (boring) academic language into child-friendly and exciting dialogue. After many editions and revisions of the script, here is the final cut of the video:

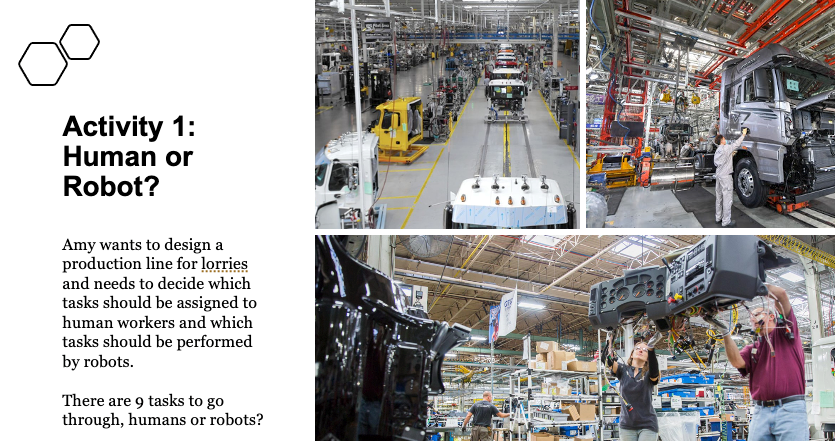

The project did not stop at the video production. We are continuing to develop further content to support the use of the video as part of a school curriculum. For our first trial, we were invited to run a workshop through Speakers for Schools program under the weekly theme of digitalization. The workshop dove into the topics mentioned in the video in an interactive manner. We wanted to hear from the students while still making it fun and educational. The workshop was divided into three sections: 1. Subject and skills for digital manufacturing; 2. Sensors; 3. Humans & Robots. I was responsible for the third section. Creating workshop content for younger audience required a completely different approach to a preparation for a conference presentation. How do we gain their engagement especially in a virtual environment? What kind of activities needed to ensure positive engagement? How do we keep them entertained instead of dozing off? How do we make it simple but still interesting? We had various brainstorming sessions to find different ways to run this workshop. We found that to keep the same narrative in all three sessions, creating a fictional character called ‘Amy’ who is a digital factory manager was the way to go. Throughout the workshop, Amy faces different scenarios where she needs helps from the students to make decisions. We used tools such as running polls, storytelling, yes/no questions, and lots and lots of pictures!

In my session of human-robot collaboration, I asked the students to help Amy assign tasks to either human operators or robots.

I was very surprised by some of their answers. The answers were mostly robots even for making coffee! To me, this demonstrates the pro-technology nature of the younger generation. They seemed to be quite comfortable with the topic and it was quite refreshing to see positive engagement from the students. Although we are now living in the world of digitalization, the final note that we left the students with was data and ethics. It is important that we are aware of potential issues and impacts that may arise from technology in order to balance the interests of all stakeholders. Special thanks to the team: Dr. Glyn Lawson, Debra Fearnshaw, Dr Adrian Marinescu, Dr Setia Hermawati, and Siobhan Urquhart.

Thank you for taking the time to read my blogpost. I hope this sparks your interests in digital manufacturing and public engagement. My name is Natalie, Horizon 2018 cohort, and my PhD focuses on the adoption of collaborative embodied autonomous systems in the case of digital manufacturing from legal perspective. 😊